We will teach you how to protect your industrial LCD screen from ESD damage. First of all, let's understand the concept, ESD (Electro-Static discharge) means "electrostatic discharge". ESD is a discipline that studies the generation, harm and electrostatic protection of static electricity.

Hair when going straight through a sweater, the little electric shock of a doorknob, we're all familiar with the discharge of static electricity. This phenomenon is called ESD or electrostatic discharge. Electrostatic discharge is the sudden flow of electrostatic charge from an object with a higher charge to an object with a lower charge. Contact or separation of materials is the main cause of ESD.

Materials used in electronics and other clean room environments are excellent insulators that can generate and maintain very high static charges for long periods of time. When ESD occurs, negative charges are picked up and distributed over the entire surface of the object. This charge can flow away suddenly if it comes into contact with another conductive object or with the ground.

Sparks or flashes of over 10,000 volts can easily occur in the modern workplace. While not a danger to humans, it could be the end of electronic devices. Due to the dielectric nature of electronic components and assemblies, devices are increasingly sensitive to ESD. The extremely thin conductive paths in active electronic components like ICS often cannot withstand high ESD. In addition, ESD damage is usually invisible and it may affect the reliability and operating life of liquid crystal display products.

The main reasons for electrostatic ESD damage to industrial LCD screens:

1. The electrostatic adsorption of dust reduces the insulation resistance of the components and shortens the service life.

2. Electrostatic discharge (ESD) damage, resulting in failure of electronic components.

3. The electromagnetic field generated by electrostatic discharge has a large amplitude and a wide spectrum. This static noise and electromagnetic interference make electronic equipment not work properly or even get damaged.

The main factors that cause static electricity:

Static electricity occurs at any stage of LCD screen production, transportation, and installation. Due to improper operation, the product is broken down by static electricity, causing potential damage to the liquid crystal display product. In order to minimize the harm of static electricity to liquid crystal displays, manufacturers, distributors and customers need to strictly abide by the standards during production, transportation and use.

Ways to protect industrial LCD screens from electrostatic ESD:

1. Environmental management

1. Control the humidity of the working environment. Especially in autumn and winter, static electricity is easy to generate in dry weather. In a dry environment, static electricity can generate thousands or even tens of thousands of volts. However, such a device with good hygroscopicity is difficult to generate static electricity. Therefore, proper humidity control of the working environment can effectively protect the display from ESD damage. The recommended humidity is around 60%.

2. Establish an anti-static work area. When carrying out assembly, use anti-static floors, anti-static workbenches, anti-static grounding wires and anti-static appliances. The anti-static work surface should maintain the equipotential of the equipment and the ground.

2. Anti-static management of staff

People are the main source of static electricity, so if workers are not grounded, the risk of damage is very high. ESD protection of workers is important when assembling sensitive electronic components. An anti-static wristband is the most effective way to avoid ESD damage. The operator is grounded through the wristband. At the same time, it is also important to wear anti-static clothing before entering the work area.

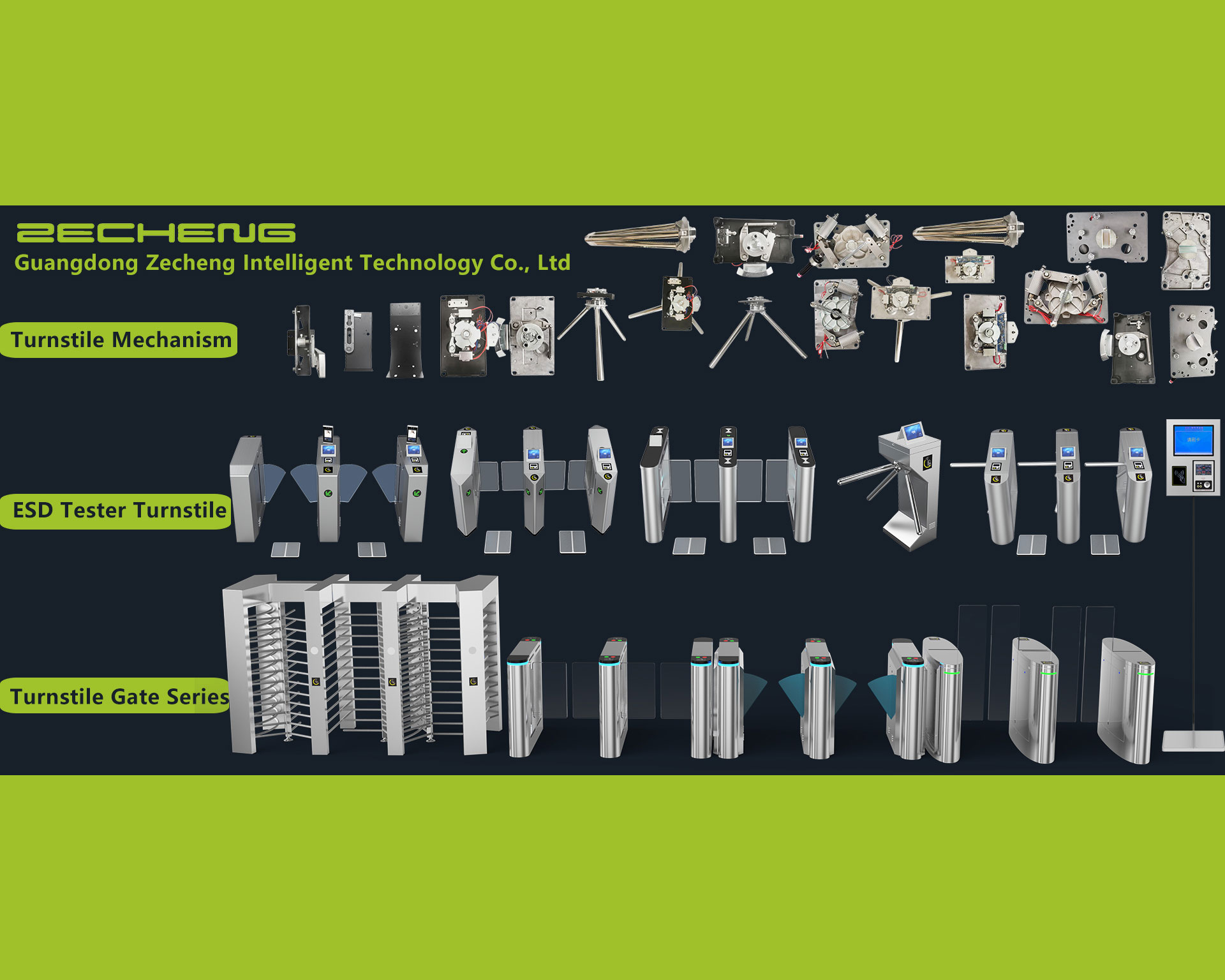

Guide for purchasing turnstile gate

Guide for purchasing turnstile gate

What are the advantages of facial recognition attendance machines and fingerprint attendance machines?

What are the advantages of facial recognition attendance machines and fingerprint attendance machines?

Digital card swiping networking electrostatic tester

Digital card swiping networking electrostatic tester

What are the classifications of turnstiles? What are the functional characteristics of the turnstile?

What are the classifications of turnstiles? What are the functional characteristics of the turnstile?